DGRT

You are here

Wireline Winch & Borehole Winch Safety

Mining and exploration safety requirements are constantly increasing. Laminar Borehole Winches address the safety challenge by design. It features a real emergency stop, minimal pinch points with no chains or exposed gears. The remote control means the operator doesn't interact directly with the winch.

Emergency Stop

Laminar Winches use electromechanical emergency stop circuitry. On activation the Winch can only be restarted by intentional positive operator actions and not by releasing the Emergency Stop button alone. Depth and system information is retained, while the motor and actuator power is disengaged.

Guarding

The winches are designed for optional guards to further protect personnel. Clear or opaque covers are available to suit regional safety requirements.

Over Spooling Detection

With closed loop monitoring a Laminar Borehole Winch can detect tension related spooling errors. On detection the winch safely stops motoring before the spooling becomes a problem. Best of all, external load sensors and calibration are not required.

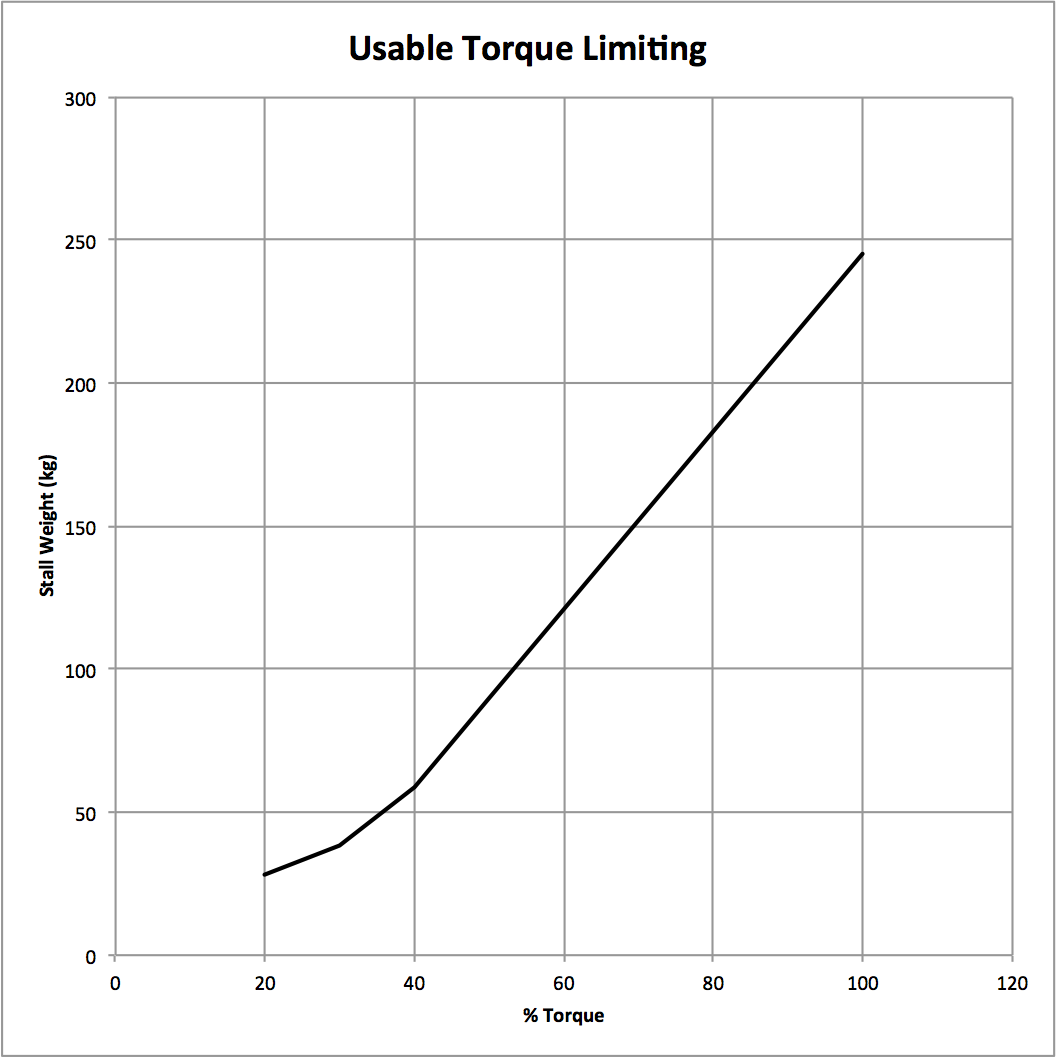

Torque Limiting

Torque Limiting

High torque wireline motors are tempered with adjustable electronic torque limiting. Setting a limit gives extra safety under normal logging conditions. Maximum torque can be selected to pull through blockages.

Keeping a Safe Distance

Perhaps the best safety feature of a Laminar Borehole Winch is the complete control from the included Hand Controller. Even the Spooling/Cable laying can be adjusted via the remote hand control, which means the operator doesn't need to be near the moving drum of the winch.

Copyright 2015 DGRT Pty Ltd